FOUR SISTERS FARM

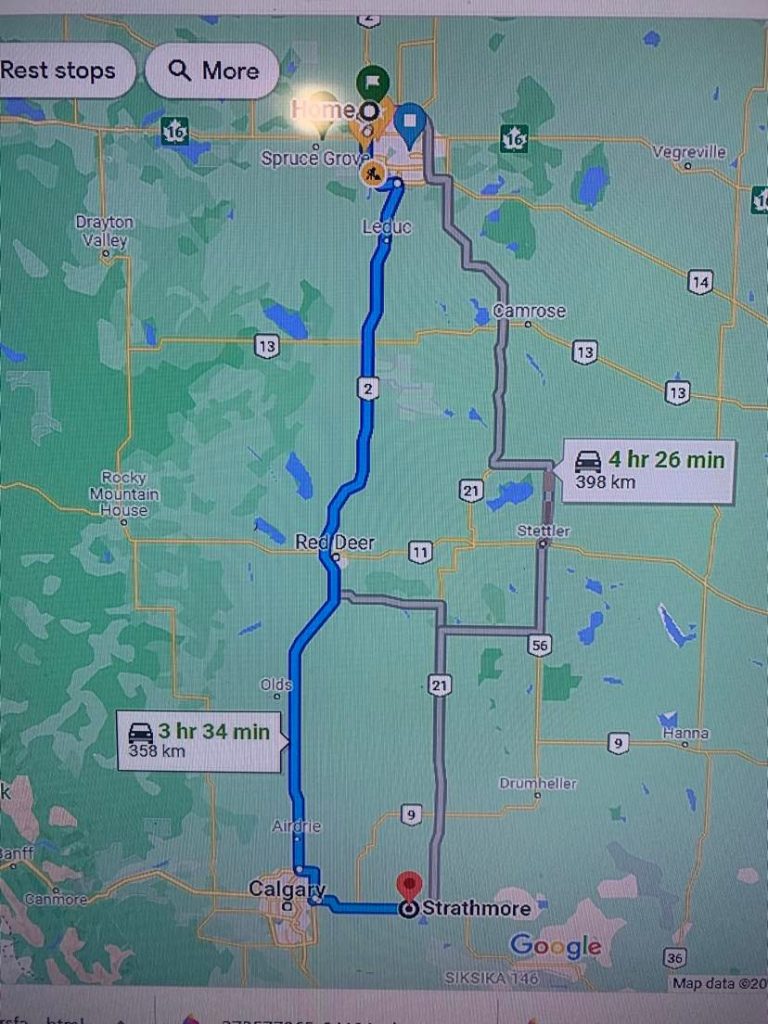

STRATHMORE, AB

(1 KM NORTH ON HWY 817)

OWNER

BRAND & PAULA BEEKMAN

PHONE

587-727-7374

EMAIL

FARM4SISTERS@GMAIL.COM

FACEBOOK

@FOURSISTERSFARM

INSTAGRAM

@FOURSISTERSFARMALBERTA

www.foursistersfarms.ca

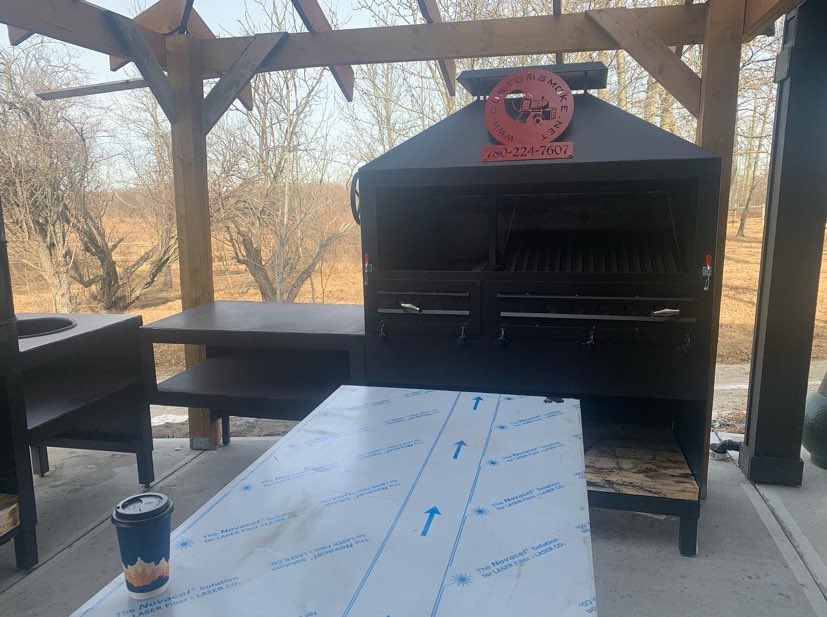

Below is progress pictures of an Outdoor Kitchen Build, this build consist of the following;

- 30” by 30” Custom Smoke Cabinet Smoker with side table

- 5’ 6” by 30” Rotisserie Lamb/Pig Cooker with side table designed to accept and Big Joe II Grill. The Cooker will be easily converted to a Chicken Cooker with grease dip pan.

- 60” by 30” Santa Maria Grill to be used with charcoal or hardwood, includes over sized side table

Fold down doors for easy access

I’ve cnc’d new hinges all for all my builds

Santa Maria Grill at the beginning of it’s life

Keeping everything square for the start helps out at the end

Crank wheel in place , still have to fab the locking assembly

Door hung in place, waiting for the hinges to be cut on the water jet

Hinges hung and working well

Doors basically stay closed without any barrel locks. Toggle locks will be installed as a locking assembly

Tacked in the log rack support system

Tacked in the Santa Maria support system, next build the Santa Maria grate and turn style

Using a 2 1/8th ” hole saw, DeWalt drill, several batteries, tons of pressure on the drill and gallons of cut fluid it only took 3 hours to drill out 8 holes through 3/8th’s of steel.

Starting on the Santa Maria grate side

Just about done, my wrist was done after this project

Log Rack-Burn your logs and the charcoal drops to the bottom, slide the charcoal over to the Santa Maria side to cook your favorite meats

Rod supports tacked in place

Installed the Hood and worked the bugs on the grates coming up and down. I believe the issue was as simple as to much play in the cabinet without the hood locking the whole unit together. Monday we start welding the entire units together including the side table mock up and then paint will start for delivery after the first week in January. Still have to make the air vents sit at 90 degrees and make all the tools for the client, such as chicken flippers, fire pokers, charcoal shovel and rakes.

Getting ready to paint, but first we had to lift the cabinet in the air to paint the bottom of the unit. So up in the air it goes!

Bolting the side cabinet to the main unit

I tack the door to the cabinet and then weld the hinges to main chamber

Almost done

Five racks for all your meat needs

Welding angle iron to the door stops the warping

Oak Handles

more handles

Cold smoke port

Still needs a handle

I don’t fit in there but I managed to get my fat ass in there

Up in the air for paint

painted!

It takes about 24 hours for the paint to dry

Sprays on glossy but the heat will set the paint to a matte finish