I’ve been given a challenge to reproduce a mini off set smoker like the picture above. I typically build reverse flow smokers and cabinet style off set smokers so this should be fun. This is made from 2 propane bottles luckily I happen to have several propane bottles that I cleaned out last summer. The propane bottles have been soaking with dish soap and water in them for several months now so there safe to cut. There’s several video’s on YouTube how to remove the gas and clean the tanks.

I’ll post daily updates on the build here on this page if would you like to follow along.

Take two of these 30 lb propane bottles, soak them in soap and

water for 2 weeks so there safe to cut into otherwise BOMB!

Only cut the top of the door and part of the sides first, weld on the top trim and tack the top trim to the main chamber, you can remove the tack after. This will keep the door from popping while your welding the trim on all the way around the bottle.

Only cut about 20% down on the left and right side,

this will allow give the door support when cutting the bottom out

Only cut about 20% down on the left and right side,

this will allow give the door support when cutting the bottom out

Grind a ground area off until you remove all the powder coated paint off, otherwise you’ll never get a good enough ground

You’ll see the trim is left long and the right and left side. I’ve tack the long side of the trim to the top and bottoms. This is for keeping the door stable. The heat from welding the trim on will pop the door, so let the tank cool down and then trim off the extra length and remove the tacks

Marrying the fire box to the main chamber, the mouth of the fire box needs to be 6″ sq inlet to the main chamber to create the correct draft.

I built the legs using 60 degree cuts both on the top of the leg and bottom of the leg. This was a fail when marrying the bottle to the legs so I just traced the leg of the bottle and it worked it self out. I’ll run a support from leg to leg after.

There’s still lots of welding and filling. You can see the gap at the bottom of the left front leg needs some help. Plus all the paint needs to be removed. If it warms up outside I’ll try grinding out in the back yard with a 40 grit wheel and finish it off with a wire wheel. The ring on the right side still needs to be removed and a we still need offset stack which is mounted on the right side. For reverse flow the stack would go on the same side as the firebox.

Still lots of work to do

Installing the bottom trim on the firebox

Trim done on the firebox, I still tack weld the overhangs while the welding cools

Stack installed, major holes to fill. I take several passes at low voltage and low wire speed

HUGE HOLE

So, I missed a little when cutting out the collector area. No turning back now

BIG BIG HOLE

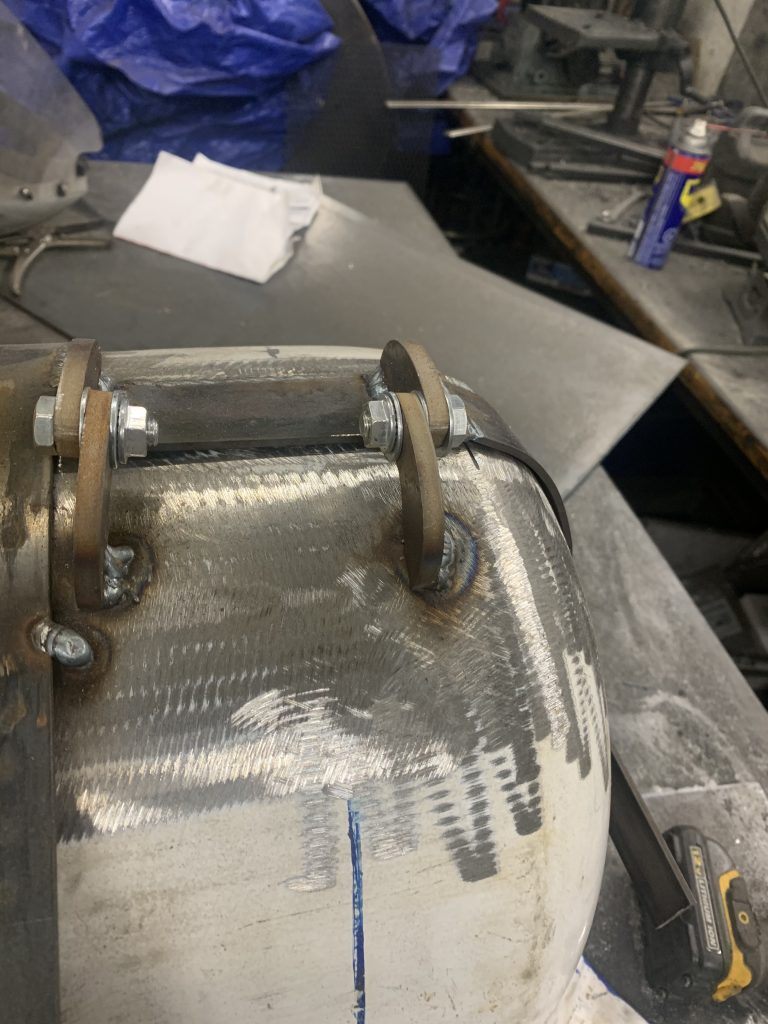

I used the same type of hinges on the fire box as the main chamber

Once the fire box cools down I’ll remove the extra trim

Leg work tomorrow

I used a 7/8th bolt to plug the valve hole

Almost ready for the burn test

I start a fire in the main chamber and fire box to burn off the old paint

Both lids opened up, general one or the other needs some rework

Still need to plug the valve hole in the fire box

Burning the old paint

It’s starting to work

See it bubbling?

Painted – Now the paint has to set and grab

Gauge set in place

Mini Grate

Firebox Charcoal Bin ready

Waiting to be delivered

Delivered – Ben sprayed the inside and outside with PAM cooking spray to season the unit

Temp siting at 235 while seasoning occurs

It’s holding temp nicely

Water bin and food cooking away like it should – The lid popped which happens on tank builds so I used a trailer latch which was purchased at PARTS STOP Spruce Grove. Simply welded the latch to the body and lid. Works great – Thanks Willis

Running a little Hot but still cooks away

Spring Handles – Amazon Prime 2 for 19.00

I hope Ben enjoys his mini smoker. Drop comments down below.